Product design

NBI has developed a proprietary software, E+ desoft and E+ Vitope to design CRB, SRB and TRB series.

NBI is continuously working on improving internal standards, internal design and analyzing alternative design configurations. The aim is to achieve maximum load capacity and thus to prolong the bearing life.

Strategic partnership with some of the most advanced Spanish technological centers: CEIT and Tekniker BRTA.

E+ vitope and E+ desoft are a © software of NBI Bearings Europe, S.A.

NBI’s raw material standards & NBI’s dimensions and tolerance standards

- International bearing and steel standards.

- Technical and scientific researches.

- Application engineering team’s findings.

- Clients’ application specific requirements or feedback.

- Accumulated knowledge based on experience, internal developments and analysis.

- Findings obtained from tribology projects

- Benchmarking.

- Cooperation with suppliers of raw material and bearing components.

- Cooperation with heat treatment, grinder and hard turning equipment suppliers.

- Models 3D + finite elements: E+asyc, Romax and Ansys.

NBI’s internal design and analysis

- Clients’ application specific requirements.

- Application engineering and design teams’ findings and accumulated experience.

- Different configuration alternatives obtained by E+desoft.

- Simulations to define the best configuration: E+asyc, Romax and Ansys.

- Define the most suitable heat treatment and choose optimum steel type.

- Define when needed the most suitable surface coating.

- Choose when needed the optimal grease.

- The tailor-made best solution to suit client’s needs.

- SolidWorks: 3D & 2D parametrical CAD too.l Model components, bearing assemblies. Generate drawings.

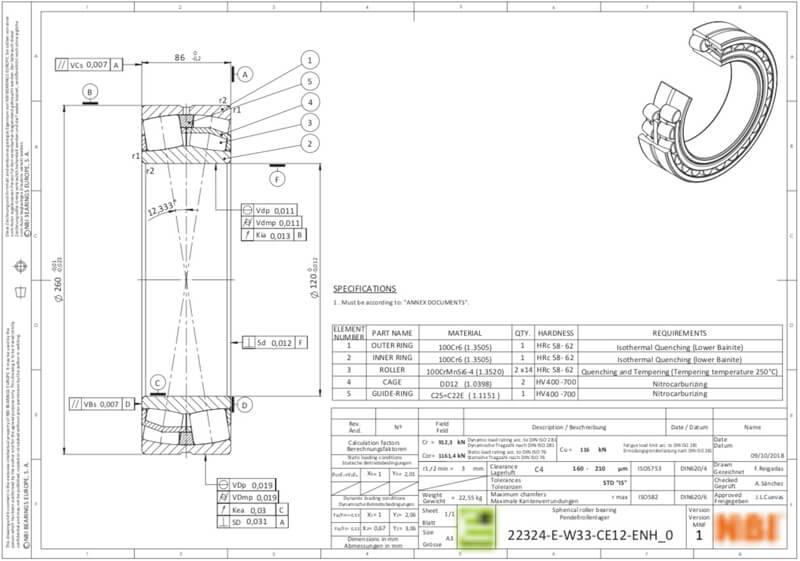

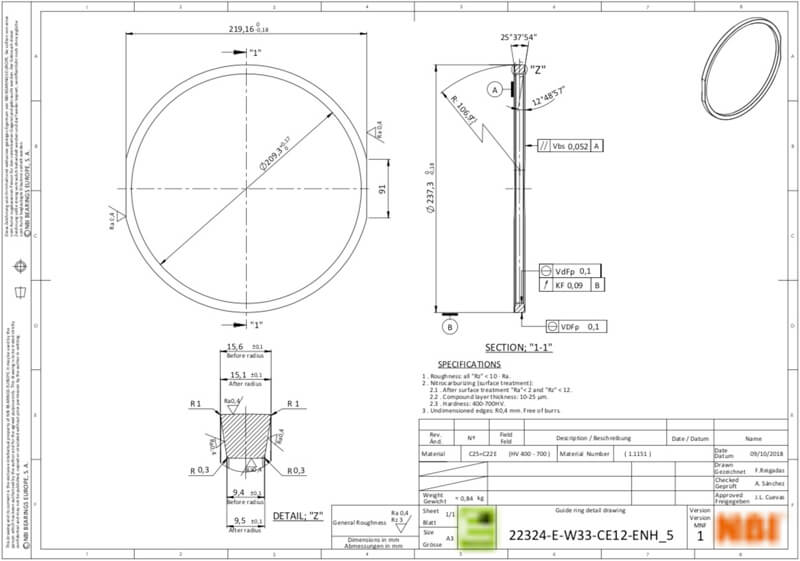

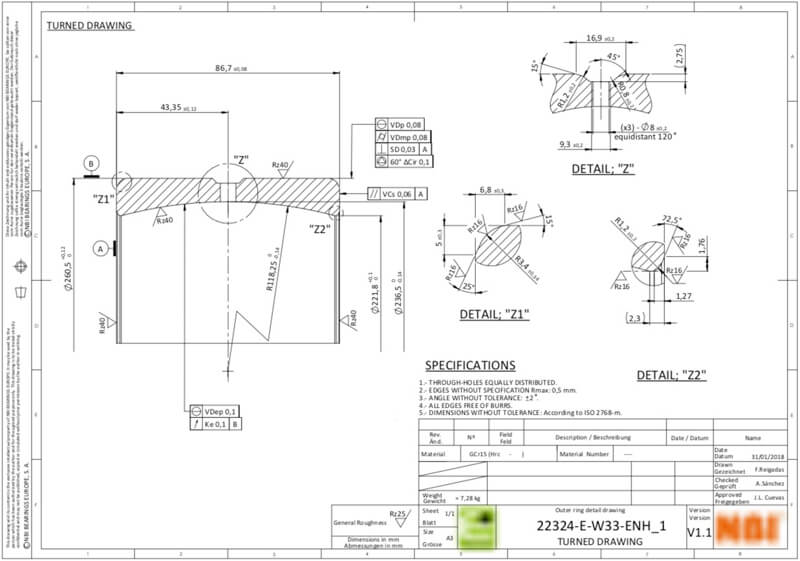

NBI’s components manufacturing drawings and specifications

Assembly drawing

Manufacturing drawing

Prototypes

Validation process

- Define field test parameters in cooperation with the client or based on own application engineering and design teams’ accumulated experience.

- Define test type and conditions for validation: life test, vibration test, salt test or any other specific test.

- Verification by a proprietary virtual tool for bearing performance (E+vitope).

Launch to the market

ENHANCED+: new bearing line

NBI combines experience in designing and producing bearings with the latest technology in material research and manufacturing technology to create a new bearing line with superior benefits:

- Improved dynamic load capacity and consequently, longer operating time.

- Reduced friction and lower operating temperature.

- Downsizing possibility

- Lower overall costs.

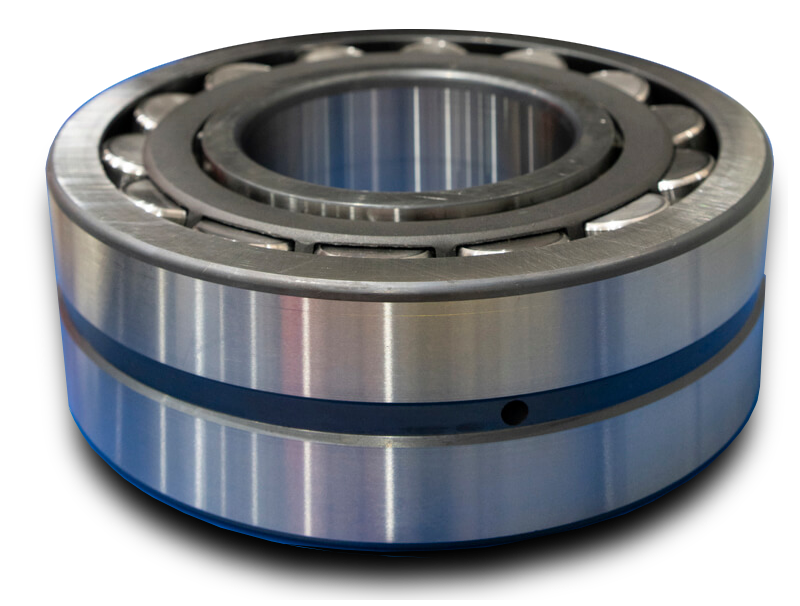

Cylindrical Roller Bearing (CRB)

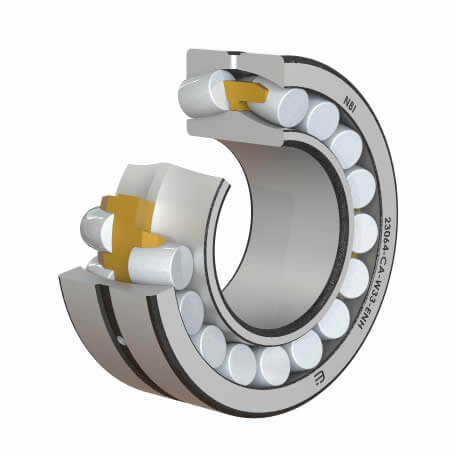

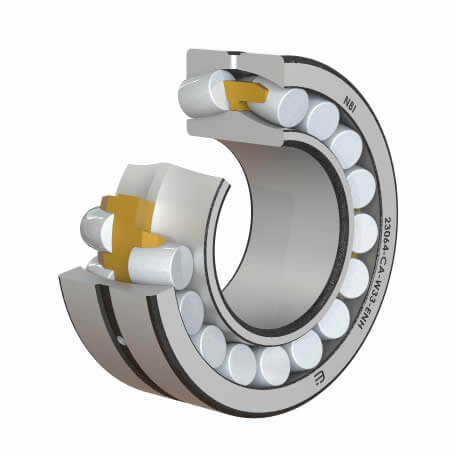

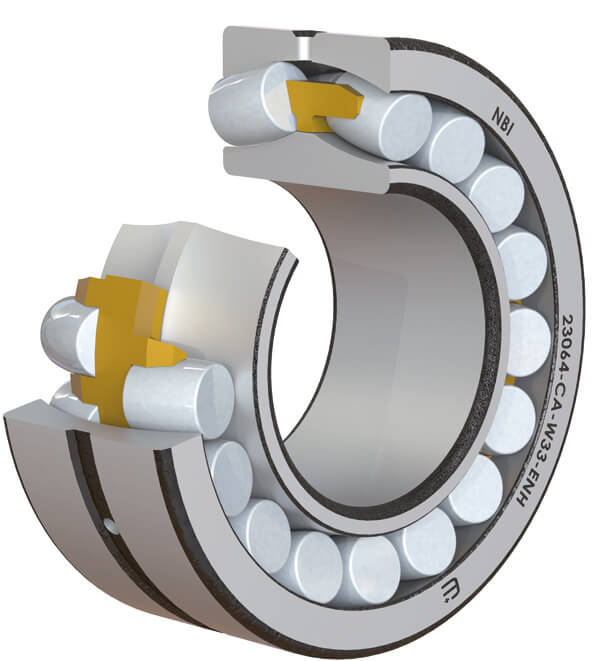

Spherical Roller Bearing (SRB)

Taper Roller Bearing (TRB)

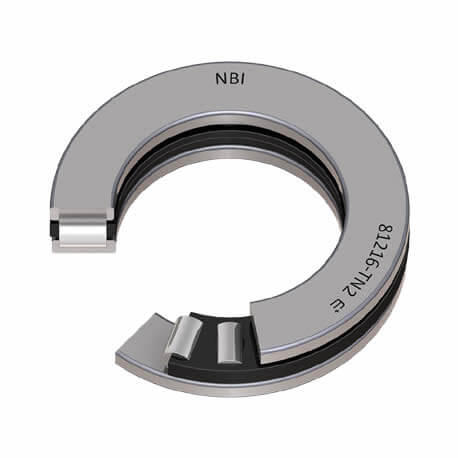

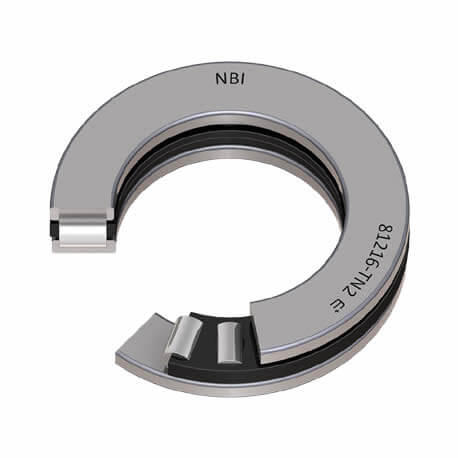

Cylindrical Roller Thrust Bearing (CRTB)

Spherical Plain Bearing (SPB)

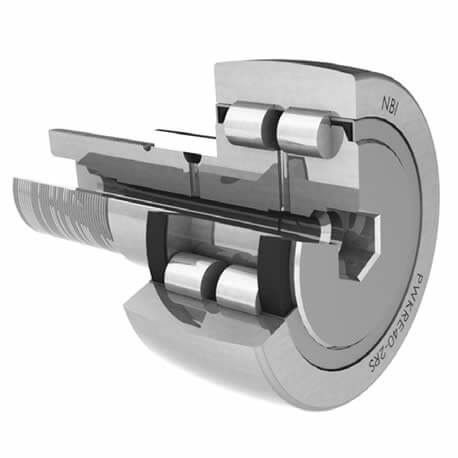

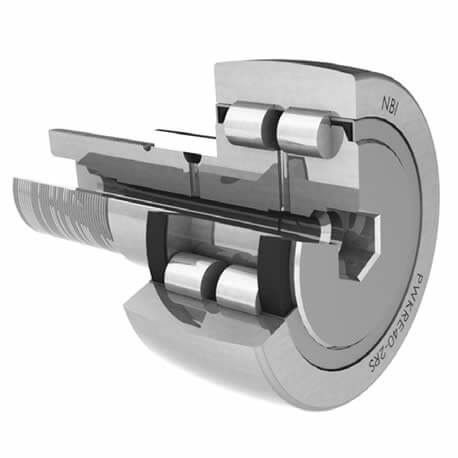

Cam Follower (CF)

Premium steel and improved heat treatment

Achieving an optimized microstructure and hardness uniformity on the functional section by:

- Selecting of through hardening steel type according to the rings’ and rollers’ thickness.

- Restricting chemical composition to closely control inclusions size and quantity.

- Narrowing carbides threshold.

- Optimizing heat treatment.

Benefits: improves bearing performance for shock loads, provides a better resistance to debris contamination and prolongs bearing life.

Heavy-duty, maximum capacity design

Optimized internal design (number of rollers, roller length and diameter) increases the contact

surface area and improves the capacity to carry loads.

Benefits: improves bearing performance for high loads.

Optimized osculation ratios

Improved contact lowers the torque, assures an optimal load distribution, reduces stress

concentrations and the rollers’ skewing tendency.

Benefits: minimizes wear, improves bearing performance for high loads and prolongs bearing life.

Manufacturing tighter internal tolerances

Reduced and controlled internal geometry tolerances optimize the components’ guidance and reduce friction and wear.

Benefits: cooler run reduces noise and vibrations.

Improved surface finishes

Superfinishing of the rollers and inner race generates constant surface features, favorable lubricant distribution and lube film. The enhanced grinding of the outer race optimizes the rollers’ traction and reduces the rollers’ skewing tendency in intense dynamic application conditions.

Benefits: reduces friction and prolongs bearing life.

Different cage designs

Cage constructions from brass or steel, guided on rollers, inner ring or outer ring in order to fulfill different application conditions.

Steel cage benefits: lightweight, high stiffness and impact resilience. Nitriding treatment benefits: superior toughness and wear resistance.

Brass cage with optimized pocket design benefits: better guidance of rollers out of load zone, reduced friction with rollers and improved lubricant flow.