Manufacturing plants

Oquendo (Spain)

Investment up to now of 10 million euros. 2.500 m² surface for manufacturing (total area 5.500 m²).

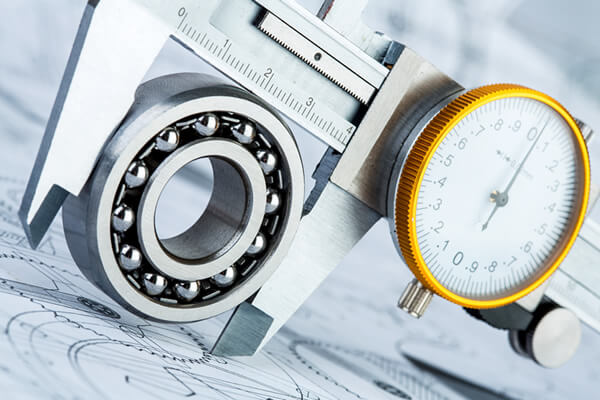

Equipped with the latest European technology, that allows to achieve high-precision bearings. All processes are performed by CNC controlled equipment.

Team formed of managers and operators with many years of experience in bearing production.

In-house metallographic, metrology and other tests laboratories equipped with the latest technology.

Long-term investment plan in place (10 million euros) with the following purposes:

- Extend the area dedicated to production.

- Increase the volume of bearing output on the already existing range (reinforcing the bottleneck capacity).

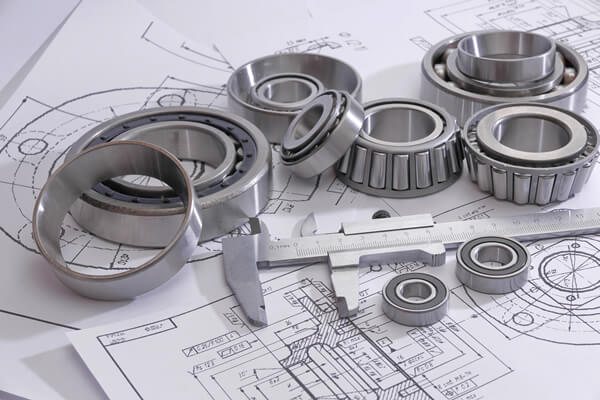

- Widen the existing range of diameter sizes and bearing types.

- Incorporate key processes in-house: heat treatment (by 2022).

Certified with: ISO 9001: 2015.

Manufacturing line

General view manufacturing plant

Automatic robot

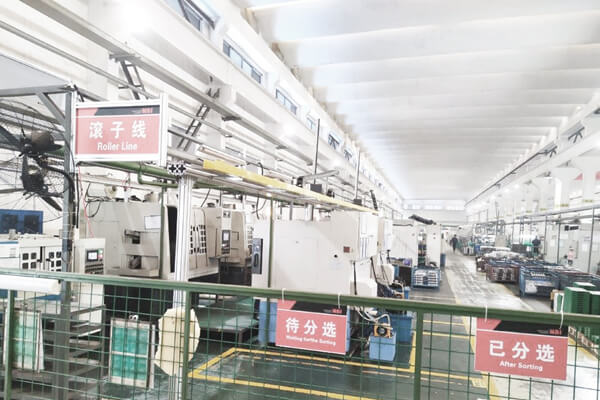

Wujin (China)

Investment up to now 18 million euros. 15.000 m² surface for manufacturing (total area 35.000 m²).

Equipped with the latest Chinese technology, that allows to achieve high-precision bearings. All processes are performed by CNC controlled equipment. 220 grinders and 40 turning machines available. 17 small, 5 medium and 2 large bearing grinding lines. Factory is equipped with an Aichelin heat treatment line. A turning workshop is also avalaible. Ability to design and manufacture its own grinders.

Team formed of managers and operators with many years of experience in bearing production.

In-house metallographic, metrology and other tests laboratories equipped with the latest technology.

Long-term investment plan in place with the following purposes:

- Extend the area dedicated to production.

- Increase the volume of bearing output on the already existing range (reinforcing the

bottleneck capacity). - Widen the existing range of diameter sizes and bearing types.

Certified with: IATF 16949:2016. TÜV

ISO 14001:2015. DNV

ISO 45001:2018. DNV

Large sizes grinding line

CRB small sizes grinding line

CRB medium sizes grinding line

Ahmedabad (India)

Investment up to date 3 million euros. 3.000 m² surface for manufacturing.

Equipped with the latest Indian technology, that allows to achieve high-precision bearings. All processes are performed by CNC controlled equipment.

Team formed of managers and operators with many years of experience in bearing production.

In-house metallographic, metrology and other tests laboratories equipped with the latest technology.

Long-term investment plan in place with the following purposes:

- Extend the area dedicated to production.

- Increase the volume of bearing output on the already existing range (reinforcing the bottleneck capacity).

- Widen the existing range of diameter sizes and bearing types.

- Incorporate key processes in-house: heat treatment.

Certified with: ISO 9001:2015. TÜV

SRB grinding line

SRB grinding line

Washing line