NBI industrial Elorrio, S.A.

At NBI we work to improve the pre-sale and post-sale commercial and technical service, with continued innovation focused on product design and quality, in order to meet our delivery commitments and to maintain a close relationship with our customers.

In order to achieve the established goals Egikor and industrias Beta, companies that are part of the industrial division of the NBI group and world references in the manufacture of metal components, stamping, and assemblies, come together, after more than 30 years of experience in the sector, in the same corporate identity: NBI industrial Elorrio.

Plant located in Elorrio (Vizcaya) with a 4.500 m² surface.

ISO 9001:2015 (PDF)

ISO 14001:2015 (PDF)

IATF 16949:2016 (PDF)

DIPLOMA EMPRESA BERDE

Products / Industry

Elevation industry: Large-scale reinforcements, assembled sets, visible parts with powder paint, stainless steel parts.

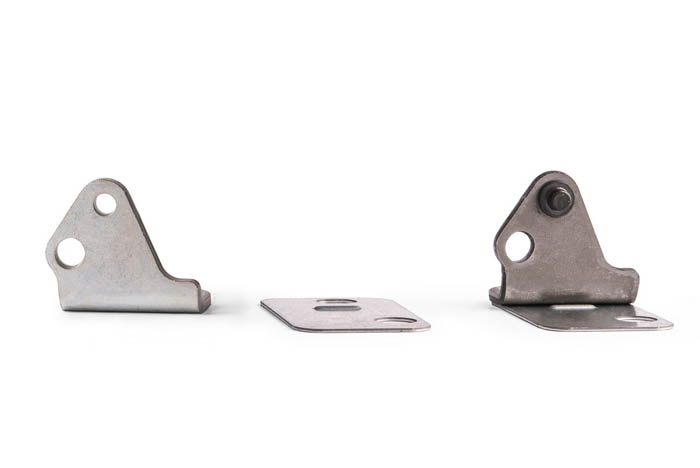

Automotibile industry: All kinds of hinges, inserts, shock-absorber covers, bushings.

Electric industry: Copper bending and stamping. Vast knowledge of copper processing means we can perform new bending and stamping operations, reducing the amount of raw material necessary, and thereby lowering manufacturing costs.

Other industries: Components and sets used in industries such as storage, capital goods, furniture. Solar power, signs and design, manufacturing of dies.

Machinery

Processed materials:

- High elastic limit steel (S550MC)

- Stainless steel

- Aluminium

- Copper

- Zinc

Welding and assembly:

- Resistance welding

- Fill-material welding: MIG / MAG / CO2

- Inserting nuts, screws, rivets, embedded elements, hemming…

Presses for progressive die:

- Capability: Up to 630 Tn

- Table dimensions: up to 3,200 mm x 1,500 mm

- Feeder: up to 1,000 mm spool width and 6 mm thickness

Manual presses:

- Capability: up to 250 Tn

- Table dimensions: up to 1,000 mm x 650 mm

Control devices:

- Three-dimensional, Profile projects HB.3507/Starret.

- Hardness tester HOYTOM Minor 69.

- Exterior and interior micrometers, goniometers, calipers.

- Artificial vision.

Surface treatments:

- Cataphoresis

- Zinc and zinc alloys

- Zinc – Nickel

- Powder paint

- Silver plating and tinning

Processes and second operations

- Grinding, machining, countersinking, threading and milling.

- Vibrating, polishing, chemical cleaning and by ultrasound.

- Cataphoresis, electrostatic painting with dust and liquid paint.

- Zinc plating, powder coating, bi-chromate, zinc phosphated, galvanized, surface treatments in the automotive industry (ZnNi, ZnCr, ZnMn, Geomet, Delta-Tone).

- Hardening and tempering, carbonitriding, induction hardening, Ionit-Ox, bainitic hardening.

Contact

Pol. Ind. Betsaide pabellón C, 48230 Elorrio (Bizkaia)- Spain

Teléfono: (+34) 943 172 550

sales@gruponbi.com