Quality at NBI is a crucial issue addressed by a highly experienced team, working closely with some of the best Spanish technology centers. NBI conducts in-depth research on bearing durability considering the manufacturing process, steel chemical composition, hardness, quench hardenability, macrostructure, and microstructure, among others.

The prior control of the material is carried out through metallographic and spectrographic examinations that are complemented by life tests on the finished product.

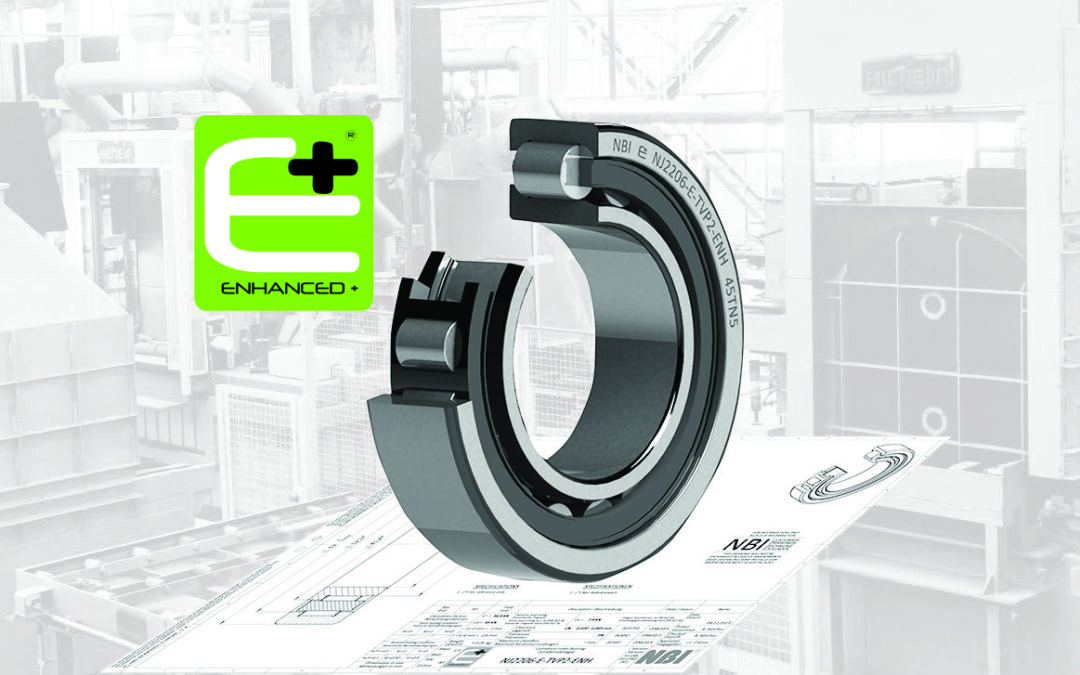

As a result of all the controls, NBI guarantees the life of the bearings with greater resistance to rolling fatigue due to:

– Improved steel cleanliness.

– Careful control of the size and quantity of inclusions by restricting the chemical composition and a desired carbide distribution

– The selection of the steel type (through hardening) based on the thickness of the rings and rollers and, being to one of NBI‘s strong points, a better heat treatment to achieve a better microstructure and uniformity of hardness in the functional section.

NBI uses the most advanced formulas and the latest heat treatment technology to achieve high precision bearings in its plants in Spain, China, and India.

More than €3 million invested in the installation of 3 heat treatment lines, 3 Aichelin salt furnaces, one of them equipped already with carburizing and the other two to be equipped in the future, allow NBI to carry out controlled heating and cooling cycles to achieve the mechanical properties – desired metallurgical characteristics in the metallic parts used in the manufacture of bearings.

The NBI plants in Spain, China and India have installed capacity for the production of martensitic hardening, bainitic hardening (case hardening) to cover a wide range of applications and specific requirements.

The application engineering team and experts in heat treatment select the most appropriate one to carry out in each bearing, depending on the application, giving it high resistance to wear, high resistance to fatigue, high structural rigidity and dimensional stability.

Coatings applied on some bearing components are an additional range of NBI products, for example, for specific requirements such as corrosion resistance (zinc coating), wear resistance (nitriding/nitrocarburizing coating), modification of the surface to improve the starting or “running-in” (blueing or coating of black oxide) of the bearing.

These applied coatings are analyzed and inspected in the laboratories (metallographic, metrology and life test) that NBI Bearings has installed in each of the plants.

NBI’s goal is to maximize bearing life

The NBI heat treatment manages to harden the functional surfaces of the bearing.

It improves the mechanical and metallurgical properties of metal parts, achieving greater resistance to wear, impact resistance, residual stresses, rigidity, etc.

And it also allows NBI to design bearings with desired characteristics in accordance with the application where it is used.