Industrial

Highly skilled person in each key position

Design engineering. Processes and components

It is focused on designing, manufacturing and supplying components and assembled parts mainly to industrial, aerospace market and automotive sector. NBI selects and invests in the optimum technology for each process and component.

Our team is currently comprised by 260 people with vast experience.

NBI created its new industrial group in order to vertically integrate the required technologies to manufacture bearing components. With that aim, NBI acquired:

- Egikor stamping plant that provides NBI with the knowledge, expertise and capacity to design and produce cages in-house and to design manufacturing processes (2016).

- Betiko multi-spindle machining plant that provides NBI with the knowledge, expertise and capacity to design and produce turned rollers (2016).

- Talleres Ermua precision CNC machining plant that provides NBI with the knowledge, expertise and capacity to design and produce turned bearing rings (2016).

NBI decided to enlarge the scope of its activities by founding the Industrial division, which is formed by two different business units: Metal transformation and Precision machining.

Since then, NBI has added two new companies with complementary technologies:

- Aida Ingeniería, together with Egikor is part of the Metal transformation business unit. Aida’s activity is specialized in the design and production of precision boiler components and assemblies for a wide range of industries (2018).

- Industrial Metalúrgicas Galindo is the latest incorporation to the Precision machining business unit. Its purpose is to design and manufacture precision tooling and machining components and assemblies for the aerospace industry (2020).

At the end of 2020, the group acquired Turnatorie Iberica creating a new business unit in the supply of aluminium components chiefly for the automotive sector. This company has incorporated to the Group the know-how in process of foundry and aluminium casting and machining.

Design engineering

At NBI we use software to design each one of our parts, components and tools.

At NBI we are continuously working on improving the internal standards, the internal design and the analysis of alternative design configurations. We collaborate with our clients from the conceptual stage of developing a product by providing our know-how and with the aim of finding the best solution in terms of quality, cost and service.

Strategic partnership with some of the most advanced Spanish technological centers: CEIT and Tekniker BRTA.

Our softwares:

- CATIA V5

- Unigraphics NX 9.3 and NX 10

- SOLIDWORKS

- POLYWORKDS 2019

- VERICUT 7.3.4

- PC-DMIS 2019 R1 and 2011 MR1

- ANSYS

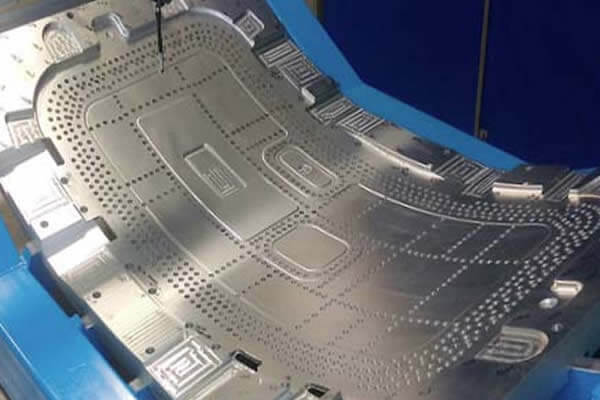

Precision machining business unit

Turning C.N.C. – C.N.C. machining center – Grinding – Bar turning

Metal transformation business unit

Press brake sheet bending – Punching Welding – Stamping – Painting

Aluminium injection business unit

Laboratories

In-house metallographic, metrology and other tests laboratories equipped with the latest technology. Strategic partnership with some of the most advanced Spanish technological centers: CEIT and Tekniker BRTA.

These fully equipped laboratories are shared by the application engineering, design, R&D and manufacturing teams.

- Taylor Hobson contour meters, roughness testers and profilometers.

- CMM Zeiss Contura G2 / CMM DEA Scirocco

- Leica electronic microscope for micro-structure analysis

- Longitudinal measuring bench

- Fatigue life test bench

- Vibration measurement test bench

- Magnetic particles inspection

- CMM Stiefelmayer

- Spectrotest TXC25

- Laser tracker

- Saline fog chamber

- Artificial vision monitoring

Personalized customer service

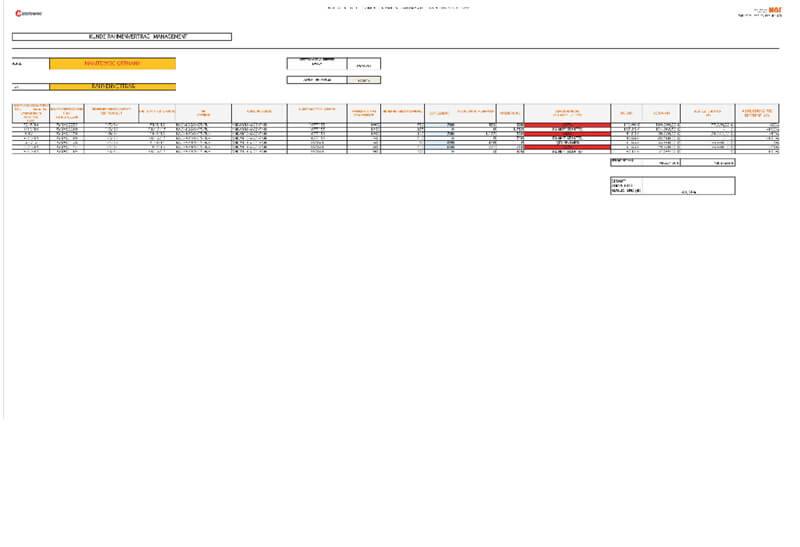

NBI proposes a commercial relationship based on frame agreements. It is a win-win flexible contract based on annual demands and commitments.

NBI’s compromises

- Maintain a percentage of the agreed contract quantity as safety stock to satisfy unexpected demands.

- Provide price stability during the period of the agreement.

- Update every month information about orders evolution, delivery commitments and real consumes.

- Better adaptation to future deliveries (based on an initial estimation and adjusted by real figures).

Client’s compromises

- Consume the quantities of the references to which the customer committed to in the period of the agreement.

- Provide a visibility of the next 3 months’ confirmed deliveries.

- Update every month’s estimations for the incoming 6 months to be able to react accordingly.

Frame agreement follow-up report

NBI’s industrial strategic industries and clients

NBI’s industrial strategic

industries and clients

NBI’s extensive experience and in-depth knowledge of a wide range of applications has positioned the company as a provider of optimum solution for many OEM manufacturers.

OEM

- Automotive

- Gas cylinders

- Lifting and lifts

- Packaging and food

- Valve components

- Engines

- Railway

- Industrial machinery

- Aeronautics

- Automation and heating

- Metal works and construction

- Bodyworks

- Urban and home furniture

- Architecture

MRO

- Automotive

- Aeronautics

- Architecture

- Engenery

- Lifting and lifts